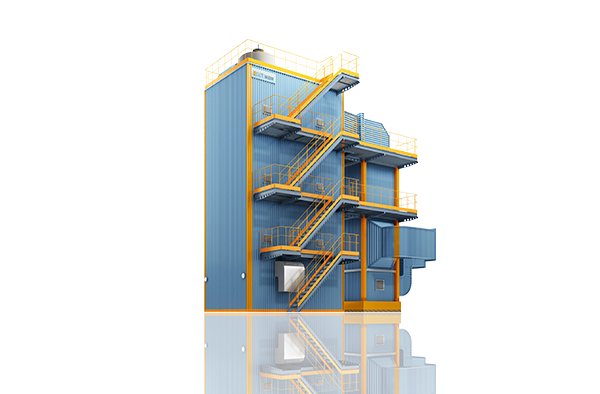

Corner tuber boiler is a high quality, efficient, energy-saving and environmentally-friendly technology introduced into China by the former Shanghai Sifang Boiler Factory in 1985 from the Danish company V?lund. It is widely & successfully applied in the s

Message